1. Overview

ShipA2Z provides fulfillment services for cross-border e-commerce businesses with warehouses throughout the United States. The free and easy-to-use ShipA2Z OMS order management system offers a better fulfillment experience. Our company covers warehousing, picking, packing, shipping, FBA forwarding, return for exchange, etc.

Please read the relevant precautions carefully before submitting inbound orders to provide customers with more efficient and effective services and ensure the warehouse’s regular and orderly operation.

2. System login and product creation

2.1 System login website: https://login.ShipA2Z.com/login#/

2.2 Product creation

- Steps: You can create products manually or batch import SKUs on the Product page. Please fill in and check the weight, size, and unit of the product accurately. If there are fixed packaging materials for inbound and outbound, please fill in the corresponding “inventory and logistics” information.

- SKU: Fill in the SKU of the product, which is used to identify the product information. If the product contains batteries, please check “Lithium” and select the corresponding battery type; the SKU filled in must be consistent with the SKU shown on the product label to facilitate the warehouse to scan the code for receive and outbound and to ensure the outbound accuracy of the warehouse. If the SKU filled in the system is inconsistent with the SKU shown on the product label, the product label printed from the system needs to be attached before shipping.

- The system automatically submits it to the warehouse for review after the product is created; however, if the actual size and weight are inconsistent with what you fill in after the products arrive at the warehouse, the warehouse has the right to modify them in the system.

3. Inbound specifications

3.1 Precautions for Inbound

- Inbound plan: Please submit an inbound plan in the ShipA2Z system before shipping. The warehouse can reject or charge the system operation fee of $100/pkg for shipments without submitting the inbound order. And the warehouse will discard the products if they have not been claimed in time.

- The packing information does not match the forecast.

-

- Before shipping: customers need to modify the forecast information and re-post the carton mark to ensure the consistency of the forecast and actual information.

- After shipping: The quantity received by the actual warehouse shall prevail. The operation time of inbound will be delayed if the data of the packing list is wrong. If customers need to expedite the process, they need to ask the warehouse whether they can expedite it and charge the corresponding expediting fee.

- Warehouse recipient:

-

- Parcel delivery: ShipA2Z+RC+ID;

- freight delivery: ShipA2Z+CR+ID (ID is OMS customer code, please consult customer service), for example, ShipA2ZRC12345.

- Delivery method: please select the corresponding arrival type (box, pallet, container size). Otherwise, it may lead to incorrect costs.

- Inbound orders Submission: when creating the inbound order, you need to fill in the logistics tracking number/container number and the estimated arrival time; After confirming the information correctness, please click submit to the warehouse and ensure that the inbound order is in Processing status.

- Arrival Notice: Customers themselves shall notify the warehouse at least two days before containers/bulk cargo are delivered to the warehouse; If customers do not inform the delivery time initiatively, it may lead to a delay in unloading the goods and the additional costs incurred will be borne by the customer.

3.2 Packing specifications for inbound goods

- Logistics distribution: The outer box needs to use rigid kraft-colored corrugated cartons and can not be covered by soft plastic film, leather, and other similar materials (customers need to pay repackaging fees if the packing does not meet the requirements).

- LTL dispatch: It is required to use standard wooden and four-bit boards. Plastic boards and other non-compliant pallets are not allowed.

- Reinforcement of goods over 50lb: If the goods exceed 50 lbs, additional reinforcement strips need to be added around the outer box to avoid the outer box falling apart during transportation and handling.

- The outer box must be in regular rectangular or square packaging. If the customer sends the non-compliant boxes to the warehouse without checking with ShipA2Z in advance, the warehouse operation will be difficult or impossible, which may result in additional fees, destruction, or be required to be transferred out.

3.3 carton barcode Requirement

- When submitting the inbound order for the first time, please take a screenshot to confirm with ShipA2Z and print the carton mark after confirmation.

- To ensure consistency of the barcode mark of the outer box of the same batch of goods, only one inbound order can be submitted for a cabinet or the same batch of goods, and the outer box must be affixed with the outer box label of ShipA2Z The system default size of the outer box label is 10*10 in.

- Barcode pasting position: Paste in the outermost layer of each box (if the packing box is attached with transparent protective film, the package label should be applied on the box before wrapping the film), and the outer box label shall be pasted on the minor side of the package. For the packaging box with the exact specification, all box labels should be pasted on the same side of the package, and pay attention not to paste in the package seal.

- Only one label is pasted on the outer box. If multiple labels are pasted, the warehouse will only cover the labels in the same direction. If the extra labels need to be covered, the corresponding fees shall be paid according to the special label service.

- No box label or barcode can be affixed to the inner side of the outer box. If a parcel barcode is found to be affixed to the inner side of the package, the ShipA2Z warehouse will not remove it.

- If the goods come without the ShipA2Z carton mark, or the carton mark can not be identified, the incoming carton mark is inconsistent with the inbound order, or the pallet is incoming without a pallet mark, etc. The warehouse needs to recheck and count manually, affecting the inbound timeframe. And the warehouse will charge an exceptional processing fee: of $1 /pkg.

- For subsidized parcels or single-item labels, the charges will be charged according to the value-added service of subsidized parcels or single-item labels.

- For returns, the charge will be charged according to the value-added service of return (before the inspection is completed).

- The warehouse will destroy parcels that cannot be connected to customers for more than seven days.

3.4 Product barcode requirements

- The non-standard SKU label includes but is not limited to: SKU label is worn and cannot be scanned, barcode scanning results are inconsistent with ShipA2Z system SKU code. If the SKU label is not standard, it needs to be re-labeled and put on the shelf in the warehouse. The SKU replacement fee of $1/piece will be charged.

- The minimum size of a single product barcode is 2.625 * 1 inch, which can be adjusted upwards according to product size.

- For the business that needs to be unpacked for product operation (such as parcel outbound), the product bar code must be consistent with the SKU code created by the system. The same SKU or similar SKU product bar code must be pasted on the same side of the package. Only one bar code is allowed on a single physical product. If it is not necessary to unpack, then the ShipA2Z warehouse will identify it according to the outside-of-the-box label.

- Each unique product needs to be affixed with different product labels. Different colors or sizes of the same product represent other products and must be affixed with different product labels.

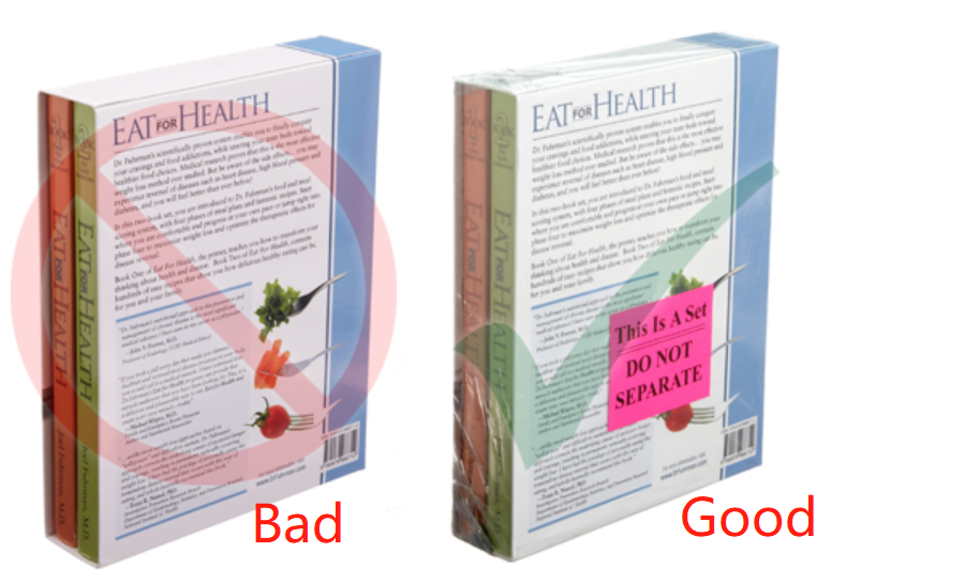

- For the product sets, it is necessary to separate them with boxes or bags and affix the label of the combined products., Labels can be defined by themselves to allow the warehouse to distinguish whether they are combined (such as figure 1.1: This is a set, don’t separate!)

4. Parcel Outbound

4.1 Submit inbound order in the system

Steps: Login to OMS system > Inbound > Create inbound order > Fill in inbound type and product information > Continue > Add sender address, headway information, and attachment information > Continue, preview inbound information > Submit > Print carton mark.

4.2 Submit outbound orders in the system

- Manual order creation steps: Login to OMS system > Orders > Create order > Add product information > Select shipping service > Fill in recipient information > Preview order > Submit order.

- Synchronize online orders steps: Login to OMS system > Orders > Click the refresh button in the upper right corner to synchronize store orders > Check the orders that need to be processed for pending status > Click “Fulfill all orders.

- Address validation: Whether the U.S. recipient address is residential will affect the shipping fee. If ShipA2Z is required to provide shipping labels, it is necessary to check the address validation when filling in the recipient information in the outbound order.

- Battery: The US domestic shipping service is relatively strict when shipping products with batteries. Please select the battery type in advance, and the battery label needs to be affixed when shipping. Otherwise, the package delivery will be affected. Please refer to the link.

- Outbound packaging requirements: The product color box cannot be used for direct shipping or palletizing. If the customer insists on shipping with their packaging, the customer will bear the loss if it is stolen or crushed in transit.

- Note: This step should be operated after the warehouse receives the inbound order and generates product inventory.

5. Forwarding / FBA forwarding

5.1 Submit inbound orders in the system

Steps: Login to OMS system > Inbound > Create Inbound Order > Fill in Inbound Type and Product Information > Continue > Add Sender Address, Headway Information, and Attachment Information > Continue, Preview Inbound Information > Submit > Print Carton Mark.

5.2 Submit outbound order in the system

- Steps: Login to OMS system > Order > Create order > Add product information > Select Freight Delivery > Fill in “Amazon Reservation Number” and “Amazon Pro #” > Fill in “Value-added Services” ( carton mark and product label ) > upload shipping request and carton mark and other attachment information in the “Message Board” > fill in the recipient information > preview the order > submit the order.

- Packing list & outbound plan: For fast inbound and outbound trans-shipment business, please provide a packing list ten days before the container arrives at the warehouse and submit an outbound plan seven days before the shipment. The outbound plan cannot be adjusted once submitted, and the outbound time cannot be guaranteed if the outbound plan is not submitted seven days in advance.

- Delivery method and pick-up time: Please fill it in strictly in accordance with the actual required delivery method, delivery type, and delivery date (reservation is not available on weekends).

- Attachment uploading: The attachment information, such as bill of lading, carton mark, product stickers, etc., involved in the Freight outbound order needs to be directly uploaded to the “message board” of the system;

- Packing requirements: If there are special requirements for packing of products, please inform the operator in advance and make a note in the freight outbound order; If there are no special requirements, the warehouse will arrange packing by default; If the customer needs to adjust after packing is completed, the customer needs to pay a repacking fee.

- Value-added services: If additional value-added services are required for freight outbound orders, please check the corresponding value-added services in the freight outbound order.

- Label format: The shipping marks and pallet stickers shall be pasted in 4 * 6 in thermal paper, and the product labels shall be uniformly in the form of 3 * 10 letter paper.

- File naming

-

- BOL: The name starts with BOL.

- Carton mark: If more than one Carton mark needs to be uploaded, the name can be Carton mark + serial number; for example, Carton mark 01, Carton mark 02 …….

- Pallet sticker: The name starts with “pallet sticker.”

- Product label: Name with the new SKU; To avoid labeling errors, only one SKU can be uploaded for the same product label file; for different new labels, please upload multiple files according to the above naming format.

- Labeling correspondence table: named “labeling correspondence table.”

- Labeling / palletizing requirements: There are fewer requirements for labeling/palletizing., The remark column of freight outbound should be marked with the corresponding relationship; If there are many goods to be operated, it is recommended to upload the file.

- Remarks must contain the following:

-

- Corresponding relationship of Labeling/palletizing etc. (If the labeling correspondence table is not uploaded).

- The labeling quantity of Carton mark and pallet sticker.

- Whether the warehouse is required to re-pack the boxes and feedback on the packing data (if there is no need, no remarks are necessary).

- Other special requirements: whether to cover the label, etc.

6. Account pre-recharge and recharge application

- All fees must be preloaded, and the first-time recharge amount shall not be less than 500 USD; Please arrange recharge in advance to ensure sufficient account balance before warehouse operation. If the balance is insufficient, the warehouse will suspend the order operation, and the customer shall bear the resulting order delay/economic loss.

- After the customer transfers money offline, please provide a screenshot to ShipA2Z customer service or sales, and submit a recharge application in the system.

- Steps: Login to the OMS system > Click“Settings”> Funding > Add Fund > Select the desired top-up method (USD for the system)> submit.

- If you select Paypal or credit card online top-up, click the corresponding top-up method, and choose the amount and account number, the system will automatically top-up your OMS account after receiving it. No need to apply. Note: Paypal and credit card online top-ups will charge corresponding handling fees, which will be borne by customers.

7. Billing & Invoice

Settlement mode

All charges in the system are “Instant Charges”, which means that the corresponding charges are deducted from the account balance when the charges are incurred.

Charges Adjustment

Because there may be additional warehouse operations during order processing or because the parcel size and weight filled in are inconsistent with actual measurement, some charges may be adjusted eventually, and the final charges will be subject to the invoice.

Billing mode

Monthly billing will be issued regularly, and ShipA2Z will send the bill to the customer’s mailbox. The charge details can be viewed by the customer by logging into the OMS system > Billing > Transaction Flow or Billing.

Billing Dispute

If you have questions about the bill, please provide feedback in WeChat or Email within three working days of receiving the invoice. The finance department will check and give feedback in time. If there is no feedback within three working days, it will be regarded as no objection to the bills by default, and we will not accept the bill dispute afterward.

8. Particular packaging specifications

8.1 High-power lithium battery packaging specifications

High-powered batteries in the United States are managed as hazardous materials. Improper battery packaging can quickly become a heat source that will cause sparks or fire. Safety regulations and appropriate preventive measures must be followed during packaging and transportation.

8.1.1 Packaging regulations

- Packaging specifications

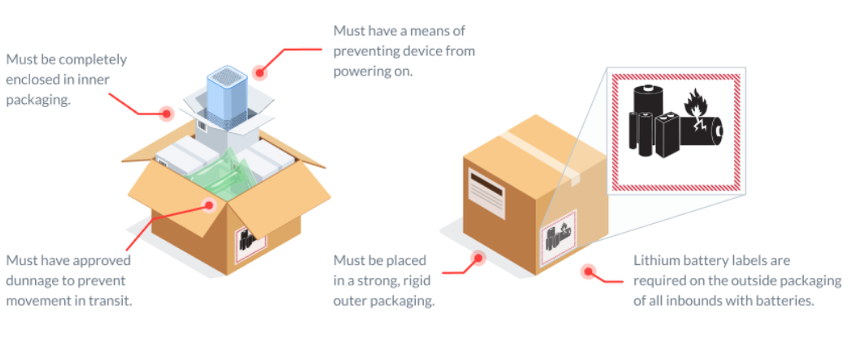

- Paste the battery hazardous material label on the outer packaging box. The battery label for high-power batteries must be in color, and the black and white label is for low-power batteries. If not pasted, the warehouse can not identify whether it is dangerous goods. The customer shall bear the extra costs or losses caused by the return or deduction of the package due to the failure to comply with the standard of dangerous goods in the shipping.

- The batteries must be placed in a thick, solid outer box when packing(as shown in the correct figure below).

- In addition to the outer packaging box, the battery must be contained in a moderately sized and insulated inner packaging and entirely within the inner packaging (as shown in the left figure below).

- The positive and negative poles of the battery need to be protected with insulating material to prevent electric leakage.

- If the space in the box is not filled, it is necessary to add insulating material with a lining to support the battery to prevent it from shaking during transportation.

- If multiple batteries are placed in the same box, the positive and negative poles of each battery should be wrapped and fixed with solid plastic film;

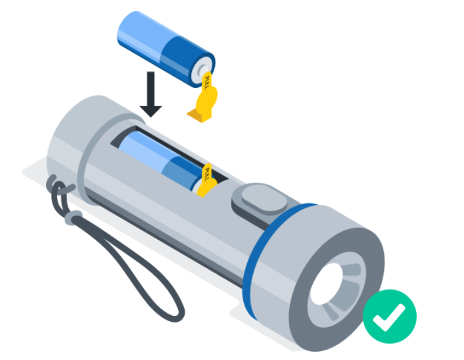

- If the battery is installed in the equipment, there is an insulated plastic pull strap at the place where the battery is installed in the kit, which needs to be pulled up to prevent the battery from being energized, as shown in Figure 1.4.

8.1.2 Precautions

- It would be best if you protected the electrodes when shipping all types of batteries to avoid fire due to short circuits. To protect the electrodes, they can be covered entirely with insulating and non-conductive materials (e.g., use insulating tape or place each battery in a separate plastic bag), or place each battery in a completely sealed inner suitcase to ensure that the exposed electrodes are protected.

- Pack the batteries properly to avoid crushing or damage and to avoid displacement of the batteries during transportation.

- Always keep the battery away from metal objects or any other material that can cause electrodes short circuits (e.g., place the battery in a separate inner box)

- To prevent fires, any equipment with batteries must be closed during transportation to avoid accidental equipment opening. Even very simple devices, such as flashlights or cordless drills, can cause dangerous heat if they are accidentally activated.

- Our company does not support shipping batteries to Alaska, Hawaii, or Puerto Rico; customers must provide shipping labels for shipment to unsupported areas.

8.2 Liquid packing specifications

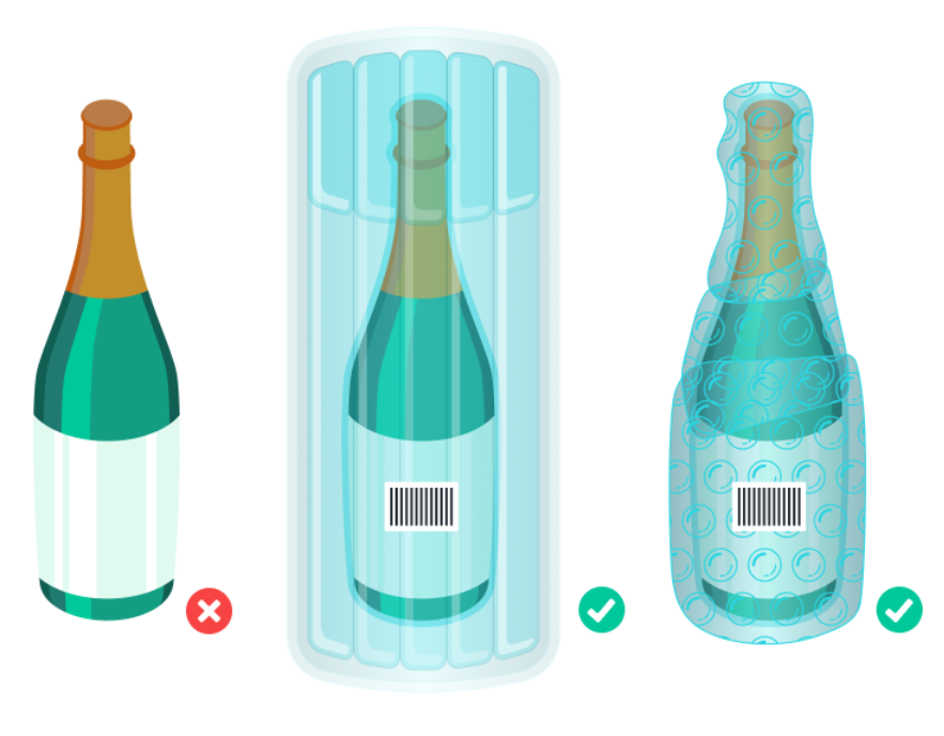

- The bottom of the cap should be sealed intact with the factory sealing strip.

- A sealed and hard tinfoil layer inside the cap should be intact.

- If it is not double-sealed as required, the bottle should be wrapped with solid-sealing plastic film and packed in a transparent and solid-sealing plastic bag.

8.3 Packaging specifications for glass products

Glass products are fragile and easily damaged during transportation and handling If they are not packed as required, they are likely to cause serious injury to operators. Because of the particularity, any destruction caused by the warehouse or the carrier during storage and transportation is unable to claim.

- Every product needs to be packed and fixed separately with qualified bubble bags.

- The extra space in the outer box needs to be filled with fillers so that each product can be stabilized in the box.

- Fill the empty glass container with fillers to avoid glass damage due to extrusion.

9. Business inquiry related

- Business requirements or batches Change: The warehouse address provided by ShipA2Z is only limited to the current time and batch of product fulfillment. The subsequent business and batches need to be reconfirmed with ShipA2Z.

- Inquiry validity: The validity period of inquiry acceptance is only one week. If it is considered over one week, you need to confirm the price and warehouse address with ShipA2Z again.

- Product Change: The inquiry product and the shipping product must be consistent. Any changes involving the product (product weight segment, SKU type, etc.) need to reconfirm the price and the receiving warehouse with ShipA2Z.

- Change of shipping Quantity: The quantity of inquired products and the actual shipped products must be consistent. The original quotation remains unchanged if the quantity difference is less than 5%. If the quantity difference exceeds 5%, the price must be confirmed with ShipA2Z again.